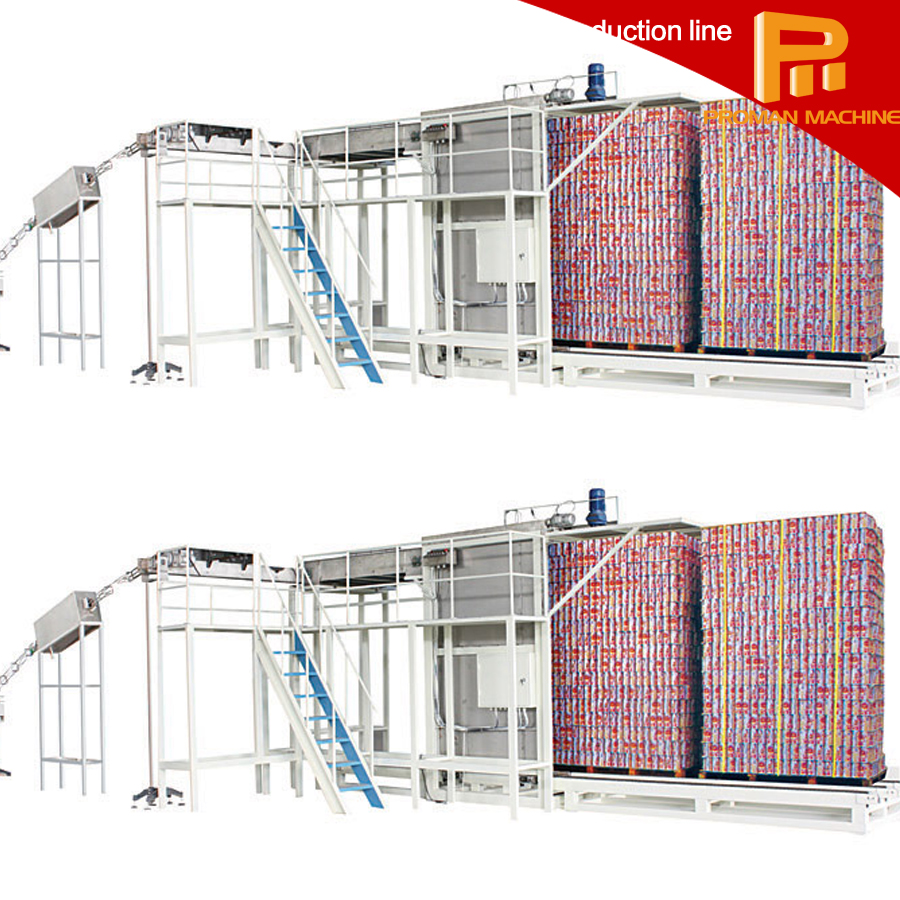

empty can depalletizer

pop can empty can depalletizer is the mainly suitable for automatic depalletizing of the complete piles of the empty cans. It hoists the empty cans palletized on the pallets layer by layer from bottom to top and then them to the conveying chain-plate. Used together with the empty can spraying washer, it can replace the manual ways arrangement and traditional empty can unloading machine, saving a lot of manpower and increasing production effects.

During the period of work, the forklift puts the pallets where empty cans are palletized onto the pallet conveyor, and the conveyor will carry them to the pallet lift platform of the main machine. The pallet lift platform is used to send the positioned empty cans to the can unloading height. When the empty can cans are unloaded, the empty pallets will fall and be put onto the conveyor. All the rising and falling actions are controlled by the self-locking lift system device. The rising or falling speed can be separately adjusted to meet the operation need. During the empty can unloading, the motor drives the chain wheel and chain device to push the cans, and then the full piles of the empty can will be pushed onto the net conveyor, and will return to the preparation position and continue to push out the next pile. All action positioning is controlled by the photoelectric switch. The can unloading with continuous actions or single circulating mode can be selected.

The pallet feeding direction, can discharging direction and operation panel position of the machine can be flexibly changed according to user requirement.

Main technical parameters:

Production capacity: 30~400can per min

Power: 3.5kw

Weight: 2500kg

Dimension: 7000*4500*3500mm